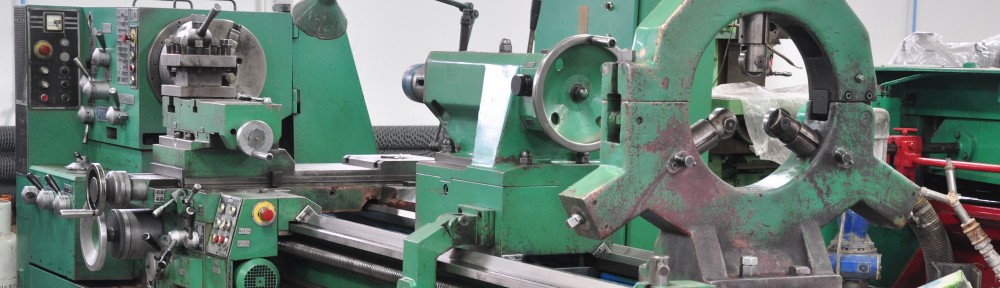

Plate bending machines are destined for pre-bending, rolling as well as obtaining conical, oval, cylindrical and other shapes of details of sheet metal. They are used for processing of steel, copper, iron, aluminum and other metals. There are different types of these devices, which differ from each other by number of bending rollers. In this article we will compare three machines, which have a three and four rollers. First our device is 3 roll plate bending machine BIKO 3 HCD B3 (foto 3). This machine is the oldest among other but it is not so old, it was produced in 1997 by Italian manufacturer. BIKO is specialized on production of high quality plate bending machines. Our next machine is 4 roll plate bending machine M G WH 510 C (foto 1), which is younger than previous and was produced in 2004 also by Italian company. MG is the leading manufacturer of plate banding machines in Italy. The last and the youngest device among our machines is 4 roll plate bending machine STOELTING VB (foto 5). It was produced only 7 years ago in 2008 by Germany manufacturer of high precision bending machines for profiles as well as for sheet metal. So, as we can see, all machines are quite new and are in a very good visual and technical condition. Now let consider their main technical parameters. First of all we have to look at the most important characteristic, such as maximum thickness of the rolled sheet metal. 4 roll plate bending machine STOELTING VB can process workpieces with the largest thickness among our devices. The maximum thickness of the rolled sheet metal of this machine is equal to 1.3 inches. This parameter of machine BIKO 3 HCD B3 is twice less and is equal to 0.55 inches. 4 roll plate bending machine MG WH 510 C can process sheet metal with the smallest thickness among our machines, which can be maximally equal to 0.375 inches. The next very important thing is maximum working length of the rollers. This characteristic is different in all machines. M G WH 510 C has the largest working length of rollers among our machines and it is equal to 200 inches. Other device of Italian manufacturer BIKO 3 HCD B3 has almost twice smaller working length, which is equal to 120 inches. And the machine of Germany manufacturer has the smallest length of working area, which is equal just to 98.4 inches. Every plate bending machine has not only different number of rollers but also has different diameter of these rollers. Plate bending machine BIKO 3 HCD B3 has one upper roller with diameter of 11.2 inches and two lower with diameters of 10.4 inches. Plate bending machine M G WH 510 C has also one upper roller, which has diameter of 13.8 inches, but it has three lower rollers, which have various sizes. They have diameters of 12.6 inches, 9.5 inches and 9.45 inches. Plate bending machine STOELTING VB has one upper and one lower roller with diameter of 17.7 inches and two side rollers with diameter of 14.2 inches. The last thing, which we will consider is weight of the machines. It is clear that plate bending machines with four rollers are heavier than such machines with three rollers. So, M G WH 510 C has the largest weight among all three machines, which is equal to 34 short tons. Germany machine STOELTING VB has a little bit smaller weight, which is equal to 27.6 short tons. And the lightest among our three machines is plate bending machine BIKO 3 HCD B3 with weight of just 8.5 short tons. So, to conclude all above information we can notice that all three machines are very good devices and each of them could be a good acquisition, but plate bending machine M G WH 510 C stands out among other with such equipment as CNC control, which makes working with this machine more easy and convenient.

CNC Machines World

CNC Machines World – is designed for professionals who use CNC machines for metalworking.