CNC lathes is a computer-controlled machines. All calculations, measurements, corrections, and the resultant submitted computer calculates movements. The man has only to write a program to your own preferences, which the cnc lathes will work. The computer will analyze its content, verify that the records will not lead to a collision and visualize them on the screen.

Each machine axis is independently controlled by a computer that receives the signal from the encoder of each axis. The first machines were stossowane stepper motors, engines then used in conjunction with incremental encoders and absolute encoders mounted coaxially. Currently, linear encoders are used, mounted independently along the axis of the machine. The encoder provides the computer so the actual value of the position of the axis. The novelty – are used increasingly linear motors.

Currently, cnc lathe consist of the following elements:

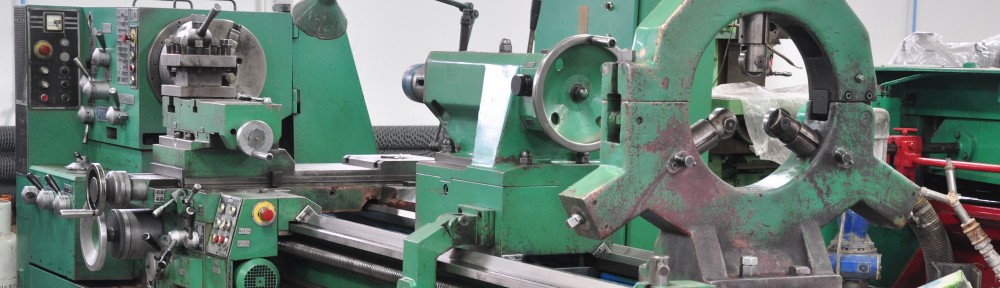

1. The main element is the body of the machine with double flat or slant.

2. The body of the machine is attached to the headstock. The spindle is controlled by an inverter or mounted electro spindle. Often, to improve the spindle power is added to the mechanical gears to provide plenty of power through the rev range.

3. The bed is screwed linear guides with strollers. Truck mounted carriage of the lathe. To allow movement of the slide, used bolt and nut. screw is mounted on the bed and driven by a motor. The nut is secured to the slide and thus rotational movement is converted into rectilinear motion. Measurement of the current position of the slide provides a linear encoder. Body encoder usually screwed to the machine body and the measuring part to the slide – in this way cnc control gets information about the actual position of the carriage. Other linear motion axes are implemented in the same way.

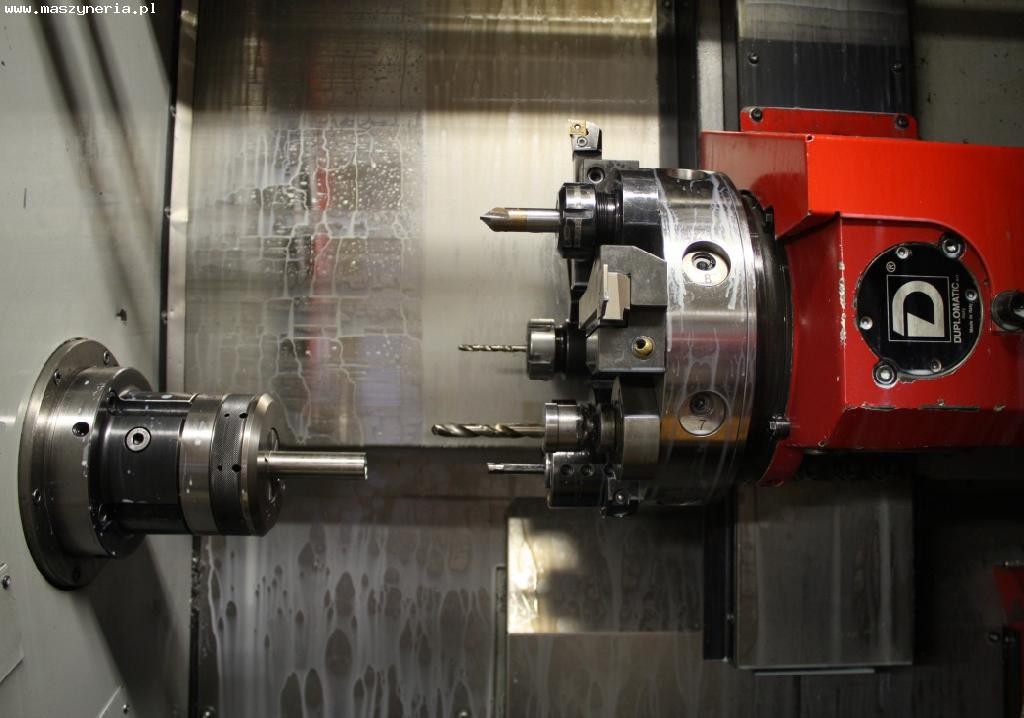

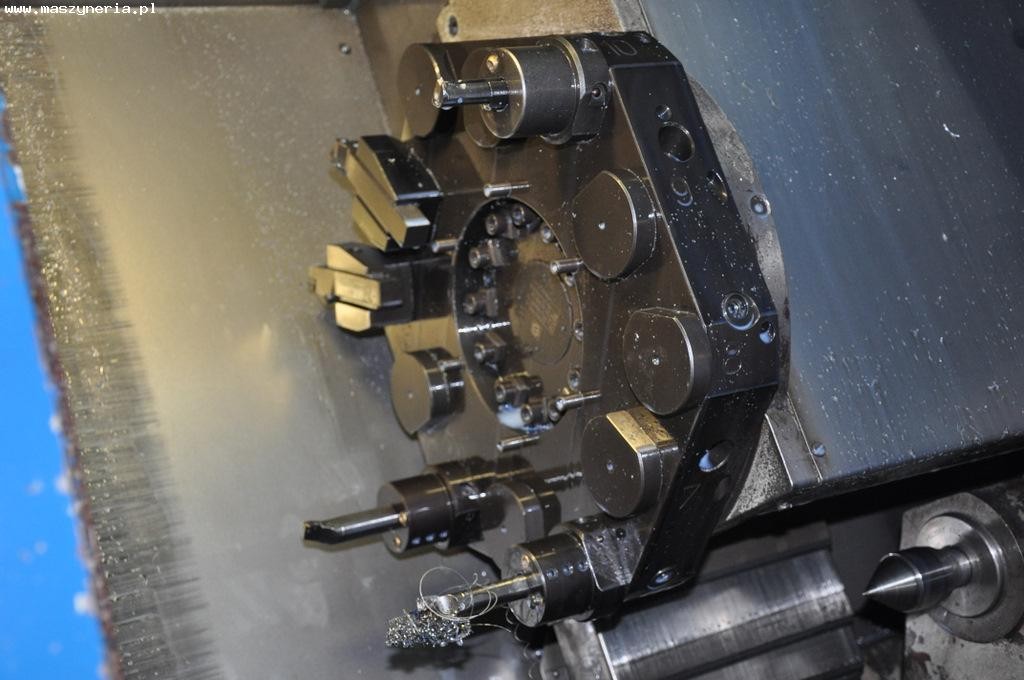

4. The carriage is screwed turret or tool holder.

5. At the other end of the longitudinal guide is installed tailstock. Tailstock is moved along the tracks manually, mechanically or hydraulically. It is used to support long workpieces.